Understanding Travertine Grades and Their Impact on Quality

Key Differences Between Travertine Grades (Premium, Standard, Commercial)

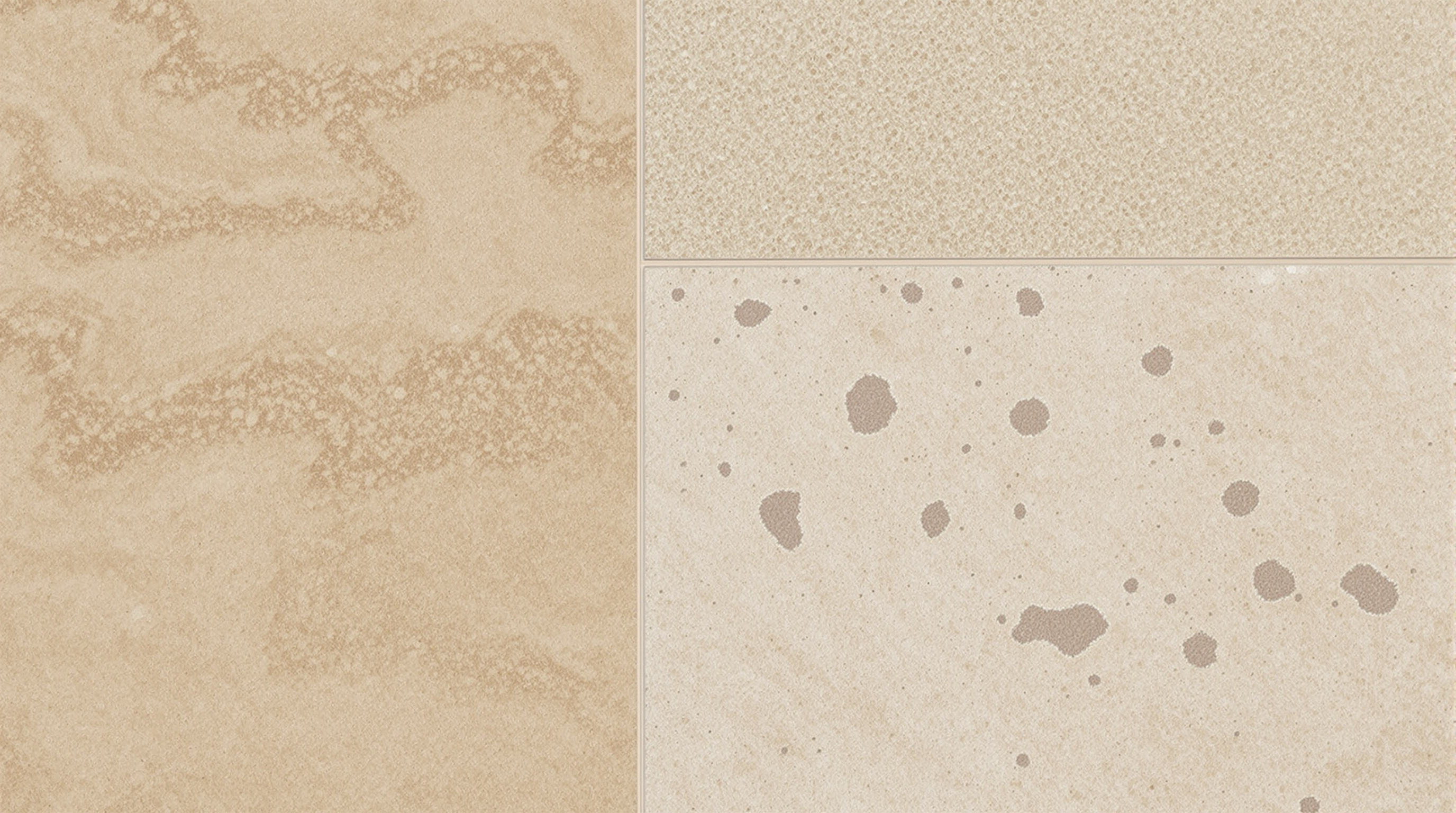

Premium travertine stone features minimal surface pitting (≤3% porosity), uniform coloration, and precision-cut edges. Standard-grade travertine typically has 5–10% visible pores and moderate color variation between tiles. Commercial-grade prioritizes structural integrity over appearance, with porosity exceeding 15% and noticeable inconsistencies in color and texture.

Why Travertine Stone Quality Varies by Grade and Quarry Source

The rock underneath makes all the difference when it comes to quality. Take travertine for example - stuff from Tivoli in Italy typically runs around 92 to maybe even 96 percent calcium carbonate content. Compare that to Turkish sources which usually sit somewhere between 85 and 89%. These differences matter because they translate into actual performance metrics. Premium stones from old quarries can handle about 30% more pressure before breaking down than the commercial grade stuff coming out of these newer mixed source operations. And here's where things get tricky for manufacturers. When companies start mixing stone from different quarries together, they end up with bigger variations from one batch to the next. This becomes particularly problematic in large scale commercial settings where consistency is everything.

How Grading Impacts Price and Application Suitability

The premium stuff runs roughly double to triple what commercial grade does because they pick out only the finest pieces and finish them by hand. People usually reserve this top quality material for fancy indoor spots where appearance matters most bathroom vanities, accent walls that make an impression. Commercial grade holds up better against constant foot traffic so it works great in places like busy retail stores or outdoor gathering spaces where people actually walk around a lot. For everyday home use, standard grade gets the job done fine on patios and behind stovetops even when exposed to some weather changes over time. It balances decent looks with wallet friendliness for most homeowners who want something nice but not necessarily museum quality.

| Grade | Avg. Price/SF | Ideal Applications | Water Absorption Rate |

|---|---|---|---|

| Premium | $18–$25 | Bathrooms, feature walls | <0.5% |

| Standard | $12–$18 | Pool decks, kitchen backsplash | 0.6–1.2% |

| Commercial | $6–$12 | Shopping malls, public plazas | 1.3–2.1% |

Color Consistency and Visual Uniformity in Premium Travertine Stone

Evaluating Color Consistency in Travertine Tiles Across Batches

Premium travertine maintains less than 3% color variation between batches when sourced from quarries using digital color-matching systems and multi-stage visual inspections. These technologies ensure consistent hue and vein pattern alignment. Commercial-grade travertine, processed in bulk, often shows 15–20% tonal variance, complicating large-scale installations.

The Role of Natural Mineral Composition in Color Uniformity

Most of the color changes we see in travertine come from iron oxide, which makes up around three quarters of what gives these stones their distinctive look. This is why we often find warm gold tones mixed with reddish shades in areas where minerals are concentrated. The banding effect comes from layers alternating between calcium carbonate and bits of organic material settling over time. When it comes to Italian travertine, colors tend to stay pretty consistent, usually somewhere between ivory and noce shades. But if we look at Turkish or Mexican sources, there's much more variety in colors available across different quarries.

Case Study: Color Variation Issues in Commercial-Grade Installations

A 2023 hotel renovation using commercial travertine required replacing 22% of floor tiles due to mismatched beige and gray tones across batches. Post-installation assessments revealed 40% higher labor costs for blending inconsistent tiles compared to premium installations. This underscores the industry practice of specifying a ±5% color tolerance for major architectural projects.

Surface Finish, Texture, and Fill Material as Quality Indicators

Smooth Surface and Minimal Pitting: Hallmarks of High-Quality Travertine

High-quality travertine meets ASTM C1527 standards, exhibiting ≤0.5 mm surface variation over 300 mm and pitting covering less than 3% of the surface. Commercial-grade stone often exceeds 8% pitting, compromising both aesthetics and long-term performance.

Assessing the Presence of Holes and Voids in Travertine Before Purchase

Inspect tiles under 1000-lux lighting and measure void depth with a calibrated gauge. Industry benchmarks suggest rejecting batches that exceed the following thresholds:

| Void Characteristic | Premium Grade | Commercial Grade |

|---|---|---|

| Average hole diameter | <2.5 mm | >5 mm |

| Voids per m² | <15 | >40 |

Filling Material and Methods in Travertine: Epoxy vs. Resin vs. Cement

Top quarries use three primary fillers:

- Epoxy: Offers 28 MPa compressive strength (ASTM C579) but may discolor under UV exposure

- Synthetic resin: Provides flexibility (1.2% elongation at break), accommodating thermal movement

- Hydraulic cement: Economical option with a 60-minute cure time

Minimal Fill and Seamless Integration: Characteristics of Premium Travertine

Premium travertine requires fill in fewer than 12% of surface voids, achieving 90% visual continuity. In contrast, commercial-grade often fills 30–45% of the surface, leading to noticeable patchwork, especially after 18 months of outdoor use.

Controversy Analysis: Polished vs. Honed Finishes and Perceived Quality

A 2023 survey of stone fabricators found that 62% of architects specify honed finishes for commercial projects due to their ability to mask wear, while 78% of homeowners prefer polished finishes despite higher maintenance. Testing shows honed surfaces retain 92% of initial slip resistance after ten years, compared to 67% for polished finishes.

Durability, Structural Integrity, and Performance by Grade

Durability and Resistance to Wear in High-Traffic Areas

Premium travertine offers three times the wear resistance of commercial grades, maintaining integrity for 15–25 years in high-footfall environments. After a decade of use, premium stone retains 92% of its original compressive strength, versus 67% for commercial-grade (ASTM C170, 2023).

Freeze-Thaw Resistance and Moisture Absorption Rates by Grade

Moisture absorption is a key factor in freeze-thaw durability. Commercial travertine absorbs an average of 7.2% moisture—more than triple the 2.1% rate of premium stone—increasing frost damage risk by 40% in seasonal climates. When properly sealed, premium travertine withstands over 100 freeze-thaw cycles without structural degradation, per EN 12371 standards.

Data Point: ASTM Test Results on Compressive Strength by Travertine Grade

ASTM testing highlights significant performance differences between grades:

| Travertine Grade | Compressive Strength (PSI) | Water Absorption (%) |

|---|---|---|

| Premium | 12,500 | 1.8 |

| Commercial | 6,800 | 6.9 |

These results support the use of premium travertine in load-bearing exterior applications.

Industry Paradox: Why Some Premium Travertine Fails Under Poor Installation

A 2023 Geological Survey found that 34% of premium travertine failures result from installation errors, not material defects—58% of which stem from improper substrate preparation. Even high-grade stone underperforms when installed with non-breathable adhesives in damp environments, highlighting the importance of system-wide quality control.

Tile Dimensions, Edge Precision, and Practical Selection Strategies

Tile Thickness and Uniformity: Standards for Premium Travertine

Premium travertine adheres to ANSI A137.1-2023 standards, allowing only ±1 mm thickness tolerance for Grade 1 materials. High-quality tiles exhibit less than 2% dimensional variation, ensuring smooth, gap-free installations on walls and floors.

Edge Quality and Sizing Accuracy’s Impact on Installation Efficiency

Tiles with precision-cut edges (≤0.5 mm deviation) reduce lippage and grout line inconsistencies. Contractors report 20–30% faster installations when using travertine that meets ANSI A108.19 edge straightness requirements, minimizing on-site adjustments.

Checklist: Criteria for Good Quality Travertine Tile Based on Visual Indicators

When evaluating travertine, check for:

- Uniform thickness across all edges (verify with digital calipers)

- Clean, chipping-free machined edges

- Natural transition of vein patterns between tiles

Strategy: Sourcing Samples and Batch Testing Before Large Orders

Obtain full-size samples from at least three production batches to assess shading under various lighting conditions. Conduct compressive strength tests on spare tiles—premium travertine should withstand ≥8,000 PSI per ASTM C170—to confirm structural reliability before committing to large orders.

FAQ Section

What is the main difference between premium and commercial-grade travertine?

Premium travertine exhibits minimal surface pitting, uniform coloration, and high structural integrity, often hand-finished, making it suitable for high-end applications. Commercial-grade travertine prioritizes structure over appearance, with higher porosity and noticeable inconsistencies in color and texture.

How does travertine grade affect its price?

Premium travertine costs approximately double to triple the price of commercial-grade travertine due to its refined selection and finishing processes, making it ideal for aesthetic-focused applications.

Can travertine withstand freeze-thaw cycles?

Properly sealed premium travertine can withstand over 100 freeze-thaw cycles without structural degradation, making it suitable for use in seasonal climates.

What is the ideal use for commercial-grade travertine?

Commercial-grade travertine is best used in areas with constant foot traffic, such as shopping malls and public plazas, where durability and resistance to wear are critical.

Table of Contents

- Understanding Travertine Grades and Their Impact on Quality

- Color Consistency and Visual Uniformity in Premium Travertine Stone

-

Surface Finish, Texture, and Fill Material as Quality Indicators

- Smooth Surface and Minimal Pitting: Hallmarks of High-Quality Travertine

- Assessing the Presence of Holes and Voids in Travertine Before Purchase

- Filling Material and Methods in Travertine: Epoxy vs. Resin vs. Cement

- Minimal Fill and Seamless Integration: Characteristics of Premium Travertine

- Controversy Analysis: Polished vs. Honed Finishes and Perceived Quality

- Durability, Structural Integrity, and Performance by Grade

- Tile Dimensions, Edge Precision, and Practical Selection Strategies

- FAQ Section